National Technology Center

Summary

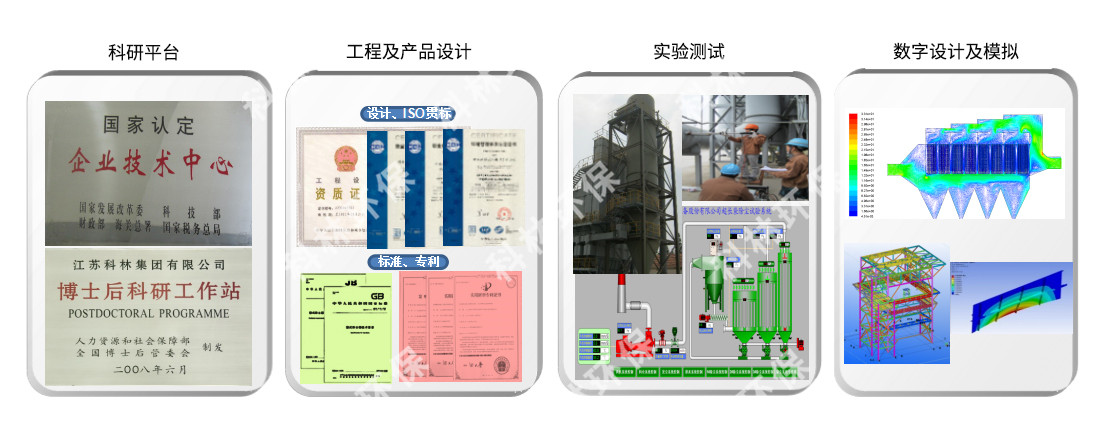

Kelin was established nearly 40 years ago and has always devoted itself to the field of air pollution control equipment. It has optimized bag filter technology worldwide. The company has a national environmental design qualification and qualification certificate for foreign contracted projects. It is a technology-based enterprise that also has a national-level enterprise technology center and a postdoctoral workstation. It is a vice president of the China Environmental Protection Industry Association and a chairman of the bag filter committee.

In 2012, the company was jointly recognized by the National Development and Reform Commission, the Ministry of Science and Technology, the Ministry of Finance, the General Administration of Customs and the State Administration of Taxation to become a state-level enterprise technology center.

The company's state-level technology center specializes in the design, research, development, consulting, and general contracting of atmospheric environmental protection projects and equipment. Currently, it has more than 100 R&D and design personnel, including 2 special allowances from the State Council, 4 researchers, and 4 professor-level senior engineers. more than 60 Senior engineers .

National Technology Center of the company has been established long—term friendly technical cooperation relationship with Tsinghua University, Zhejiang University, Southeast University, Nanjing University of Science and Technology, Jiangnan University, Suzhou University of Science and Technology and the Netherlands Institute of Technology, Japan SHINWA, New Japan Railway, Japan Spender, Denmark SAMTKE, United States EEC, Siemens VAI and PW in Germany

The company's state-level technology center has an atmospheric environmental control product testing and testing center to conduct test tests on operating conditions and new product development. The main testing equipment of the testing center are 95 units (sets), a professional dust testing laboratory and a dedicated pulse jet testing device are built. The experimental device adopts a 1:1 specification ultra-long filter bag for a variety of dust stripping sprays. Blowing technology and experimental research on diversion technology provide important guarantees for the design and research and development of filter equipment and provide customers with important services such as on-site data acquisition testing

The company's state-level technical center has a digital design and simulation laboratory, and explores and continuously optimizes the distribution technology of the air flow field of the filter. The professional CFD fluid analysis software can be used to know the distribution of air flow before and after diversion, so that the diversion design of the gas flow field is more scientific and reasonable. At the same time, it provides the best solution for increasing the life of the filter bag and reducing the structural resistance.

At present, the technology center has developed more than 30 series and more than 400 specifications of filter and environmental protection equipment;

Successfully developed and designed: large-scale electric furnace filter, dry bag filter of blast furnace gas, dry and wet desulphurization by sintering, dry-type desulfurization, denitrification and filter for industrial coal-fired boilers, electric bag dust removal, household garbage, hazardous waste, sludge, and titanium dioxide , Light bulb production line Ultra-fine particle dust removal and recovery of the total package project;

More than 30 high-tech products with independent intellectual property rights have been developed, and a number of technologies have been listed in the list of major environmental protection technology and equipment of the Ministry of Industry and Information Technology;

Kelin successively undertook the national science and technology researchproject, the national major equipment nationalization technology innovation project, the 863 project, and the Jiangsu major scientific and technological achievements transformation project;

There are dozens of "National Key New Products" and "National Torch Plan Projects";

The Ministry of Industry and Information Technology has won the title of the first batch of air pollution control regulation companies, and the Brand Top 50 of Jiangsu Provincial Autonomous Industry ;

Obtained qualifications of the Ministry of Housing and Urban-Rural Environmental Protection Class B design and 3A class enterprise credit, EU CE, EN1090,

Host or participate in the formulation of 7 national standards, 4 industry standards and 14 enterprise standards;

Nearly 100 patents were developed and more than 60 papers were published.

……

Technology, product honor over the years

Living garbage Incineration Flue Gas Synergetic Treatment Technology" won the third prize of China Machinery Industry Science and Technology Award

“LCCKE type 10 meters long bag pulse bag filter" won the third prize of China Machinery Industry Science and Technology Award

"High temperature and high humidity pulse filter for sludge incineration" won the third prize of China Machinery Industry Science and Technology Award

"LDCM three-state split combined electric bag filter" won the third prize of Ministry of Environmental Protection Science and Technology Progress Award

"Pulse Bag Filter for Coal-fired Boiler" won the National Torch Plan Project

“Blast Furnace Gas Dry Clean Bag Filter” won the National Torch Plan Key Project

"LGM/KE series coal-fired boiler bag filter" won the third prize of China Machinery Industry Technology

"Trail semi-dry desulfurization tower device" won the title of high-tech products

"Comprehensive dry purification desulfurization, denitrification and dust removal technology for coal-fired industrial boilers" won the title of high-tech products

"100t electric furnace flue gas multiple trapping efficient filter technology" won the title of high-tech products

"Industrial hazardous waste incineration bag filter with protective device" won the title of high-tech products

"Biomass boiler smoke cyclone trapping bag type filter integrated device" won the title of high-tech products

"LGM/KE Series Coal-Fired Boiler Bag Filter" won the Third Prize of Environmental Protection Technology

"Coke oven dry quenching system coal truck dry explosion-proof pulse bag type dust removal technology equipment" science and technology trade action special project certificate

The LCPM side-spray low-voltage pulse filter was successfully developed and won the national patent and ministerial scientific and technological achievement award.

150 tons of DC electric arc furnace supporting 28000M2 anti-blow large bag filter was successfully put into operation, which was ranked as the highest in China by the development center of the State Council.

Large scale blast furnace gas dry purification pulse bag filter technology industrialization project was listed in Jiangsu Province major scientific and technological achievements special funds project

The first new product, LSB pulse jet bag filter, was certified by the Ministry of Labor and Personnel and won the provincial and municipal scientific and technological achievement award.

FSF three-state anti-blow bag filter, won the provincial and ministerial level scientific and technological achievement award

Awarded by the Ministry of Machine-Building Industry as a Famous Brand of ChineseMachinery Industry

Won the title of national key high-tech enterprise

Won the title of the first national grain and oil outstanding scientific and technological innovation enterprise

Won the title of Jiangsu province energy-saving emission reduction technology innovation model enterprise

……

Part proprietary patents

| Patent name | Patent number / application number |

| Converter gas dry cleaning bag filter | ZL200620113544.X |

| A bag filter modified by electrostatic precipitator | ZL200720103940.9 |

| Wet bag filter | ZL200610078074.2 |

| Coal gasifier high pressure bag filter | ZL200920150106.4 |

| arge capacity gas box pulse cleaning combination technology device | ZL201020255900.8 |

| Ceramic filter cage high-temperature bag filter | ZL201020255950.6 |

| Metal filter cage high-temperature filter | ZL201020255948.9 |

| High pressure and high efficiency pulse jet blowing pipe | ZL201020609470.5 |

| Pulse bag filter cleaning pressure measuring device | ZL201110338923.4 |

| Bag + ESP bag filter | ZL201110374883.9 |

| Bag filter with inner bag cage and filter bag which combined with tube sheet | ZL201110394637.x |

| Large hopper and ash discharge assistant device | ZL201110397119.3 |

| Bag filter and anti-condensation gas cleaning system and heating system | ZL201120497961.X |

| Biomass-fired boiler cylindrical cyclone bag type direct-injection filter | ZL201220561981.3 |

| Bag filter for controlling PM2.5 fine particles | ZL201220569179.9 |

| Flue gas desulfurization and denitrification integration system equipment | ZL201220569737.1 |

| More than 10 meters long bag pulse filter | ZL201320218627.5 |

| Bag filter suitable for low temperature environment | ZL201310149064.3 |

| Long bag pulse filter middle housing inlet structure | ZL201320216225.1 |

| Sintering flue gas comprehensive control device without electrostatic filter and booster fan | ZL201320850734.X |

| LF refining furnace trap cover | ZL201320850732.0 |

| High volume wind cyclone | ZL201320850845.0 |

| Liquid Iron dust suppression cover | ZL201320850731.6 |

| Roof smoke retention dust capture cover | ZL201320850830.4 |

| Smelting furnace flue gas diversion integrated capture equipment | ZL201320851001.8 |

| Semi-dry deacidification reaction tower dust pneumatic conveying device | ZL201320850318.X |

| ESP+Bag combination and shunt three-state filter | ZL201310714006.0 |

| Wet bag filter | ZL201420123104.7 |

| Deduster with anti-condensation compounding device | ZL201420613231.5 |

| High-efficiency wet desulfurization and electric demisting device | ZL201520119003.7 |

| Electric defogger | ZL201520119004.1 |

| Rotary centrifugal bag filter | ZL201520188671.5 |

| Multi-pollutant intelligent cooperative control system for garbage incineration flue gas purification | ZL201520313074.0 |

| Desulfurization, dust removal and low-temperature denitrification integrated purification device | ZL201520474868.5 |

| Active ammonia and low-temperature catalyst combination denitrification device | ZL201520474948.0 |

| Semi-dry desulfurization, deducting and low-temperature denitrification combined purification device | ZL201520475366.4 |

| Multifunctional filter bag structure | ZL201520476491.7 |

| semi-dry flue gas desulfurization device with single venturi structure | ZL201520882644.8 |

| Coal-fired industrial boiler flue gas full-dry ultra-low emission purification equipment | 2016210539037 |

| Tower type desulfurization and denitrification device | 2016210537455 |

| Coal-fired industrial boiler flue gas wet-dry ultra-low emission purification equipment | 2016210539056 |

| Removal dedusting device | 2016213965731 |

| Sprinkling shed deacidification tower | 2017203301705 |

| Anti-corrosion and anti-condensation high-temperature filter | ZL201720339341.0 |

Host or participate in the formulation of national standards, industry standards

GB/T 6719-2009 | Bag filter technical requirements |

GB 17440-2008 | ust processing and storage system and dust explosion safety regulations |

GB/T 32155-2015 | General technical conditions of bag filter systematic device |

GB/T 33017.1-2016 | Technical requirements for the evaluation of high-efficiency atmospheric pollutant control equipment Part 1: General rules for preparation |

GB/T 33017.3-2016 | Technical requirements for the evaluation of high-efficiency atmospheric pollutant control equipment Part 3: Bag filter |

(GB/T 34607-2017) | Technical requirements for evaluation of operation effect of steel sintering flue gas desulfurization and dust removal equipment |

20151932-T-303 | Filter unit design and installation technical requirements |

JB/T 8471-2010 | Bag filter installation technical requirements and acceptance specifications |

JB/T 8534-2010 | Inner filter chamber opposite blowing type bag filter |

2016-0477T-JB | Long pulse bag filter |

2016-0481T-JB | Pulse bag filter electronic control device |